Integrated Package

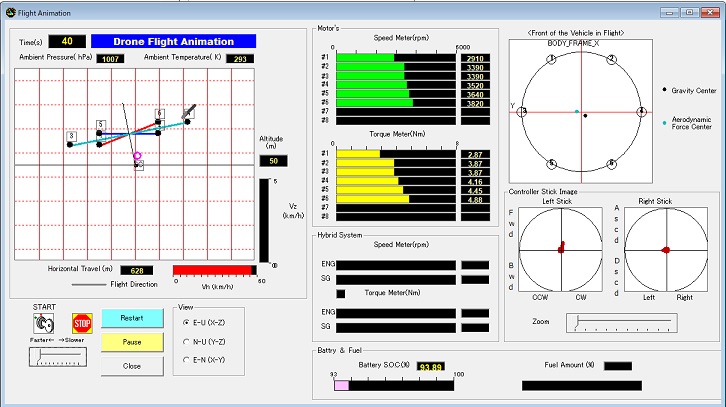

Software for Multi-copter Flight Simulation

DroneV 4.0

The Operation Windows and User Manuals are All

Described in English

DroneV is a package software for simulating flight

performance such as cruising range, acceleration and maximum speed of drones.

While

the general-purpose 1DCAE tool builds a model by combining sub-models and

modules created using many optional product groups

for

system level simulation of drones, Drone V3 has the series functions from

creating aircraft model , flight mode file, payload

file, and wind files

required for system level simulation to output flight

results.

Wha’s

New @V4.0

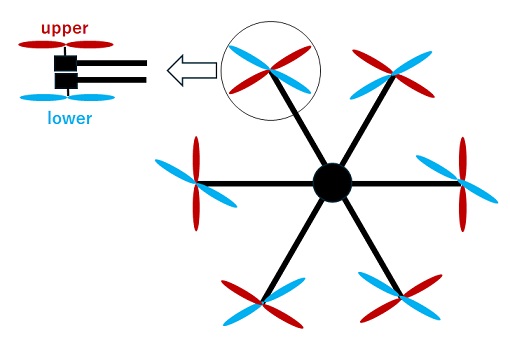

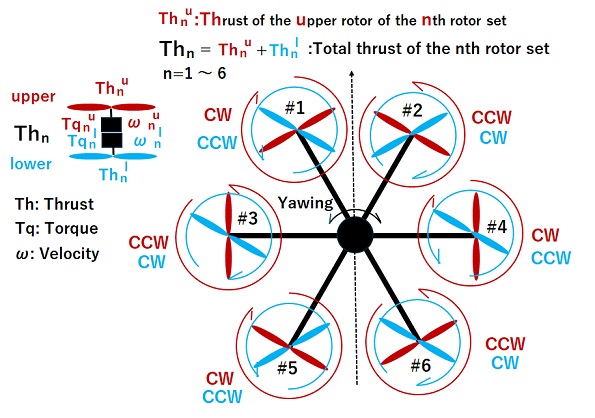

DroneV4.0 supports to simulate the

flight of multi-copters that use contra-rotating rotor unit, which has two

rotors arranged in

upper and lower

stages to obtain large thrust for transporting and delivering goods. The upper

and lower rotors of each rotor set are

each driven by

independent motors to control the vehicle's pitching, rolling, and yawing

attitude, as well as altitude or velocity.

Hexa-copter

with contra rotating rotors Click the Figure Above to Watch the YouTube Movie Click the Figure Above to Watch the YouTube Movie Click the Figure Above to Watch the YouTube Movie

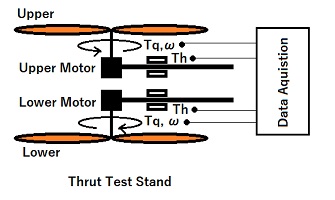

(1) How to Model the Contra-Rotating Rotor

1.

Thrust Stand Test of the Contra-Rotating Rotor Unit

Measure the thrust , torque, and speed of the upper and lower rotor

using a commercially available or

in-house thrust stand.

Schematic of Thrust Stand Example

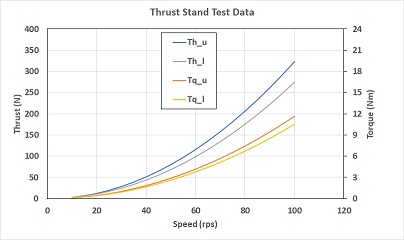

of Thrust Stand Test Data

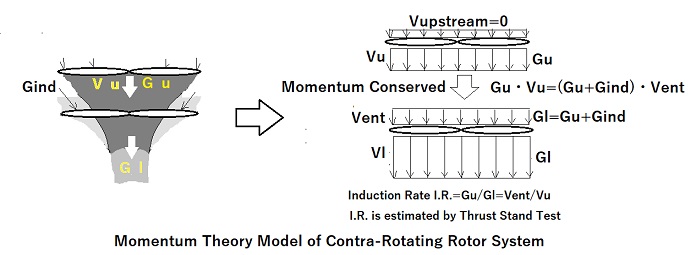

2. Modeling Applying Propeller Momentum

Theory for Contra-Rotating Rotor

Referring to the thrust stand test data

entered in Excel sheet to create the aerodynamic model

of contra-rotating rotor, determine some

parameters in the model.

.

(2) Control of the Rotor Speed

1. Pitching, Rolling, and

Altitude or Velocity of the Vehicle

The

attitude angles except for yawing and altitude of the vehicle are controlled by

the relative difference

in the

total thrust of the upper and lower rotor Thn between each rotor

set.

Rotating Motion of All Rotors

in Contra-Rotating Rotor System

2. Yawing

The main purpose of using contra-rotating rotors in airplanes and

helicopters is to cancel the reaction torque of

the two rotors. However, if two rotors with a same pitch are arranged

in series and rotated at a same speed,

differences in thrust and torque between the two rotors will appear.

Therefore, a variable pitch mechanism is

required to solve this problem.

On the other hand, fixed pitch rotors are used in multi-copters in

pursuit of weight reduction and mechanical simplicity,

but the speed can be controlled by an independent motor for each rotor

instead, and Yawing torque can be controlled

by the differential speed of the upper and lower rotors.

The control target is

yawing angular velocity or yawing torque, and the manipulated variable is the

rotational speed

difference Δω between the upper and lower

rotors, and there are three control methods when the target yawing torque

is zero, as shown below.

◆Speed-Based Control

Speed difference Δω = 0, and although the

reaction torque is not balanced for the individual rotor set, the overall

vehicle is balanced.

◆Torque-Based Control

Based on torque difference Δtq=0 to balance the torque in each rotor set, but the speeds of the two rotors are

different.

◆Thrust-Based Control

Thrust difference Δth = 0, and although the

reaction torque is not balanced for the individual rotor set, the overall

vehicle is balanced.

The operating conditions (thrust, speed, and torque) of each rotor will

differ depending on the control methods above.

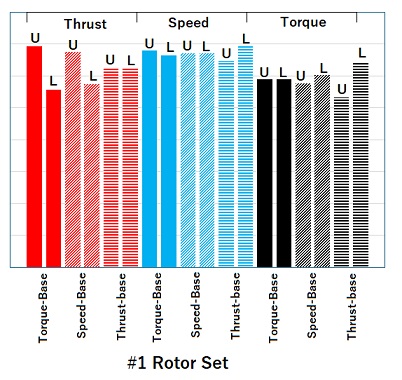

3. Comparison of Rotor Operating Conditions(Thrust/Speed/Torque) by Yawing Control Method

The simulation results using a Hexa-copter model are shown below.

a) Hovering

Figure a) below shows the

operational data of the #1 rotor set when the vehicle with its center of gravity on the

Z-axis is hovering

in a windless environment. Comparing the

upper and lower (U, L) rotors, it can be seen that in

speed-based control, the speed of both

rotors is the same, in torque-based control, the torque is the

same, and in thrust-based control, the thrust is the same as well.

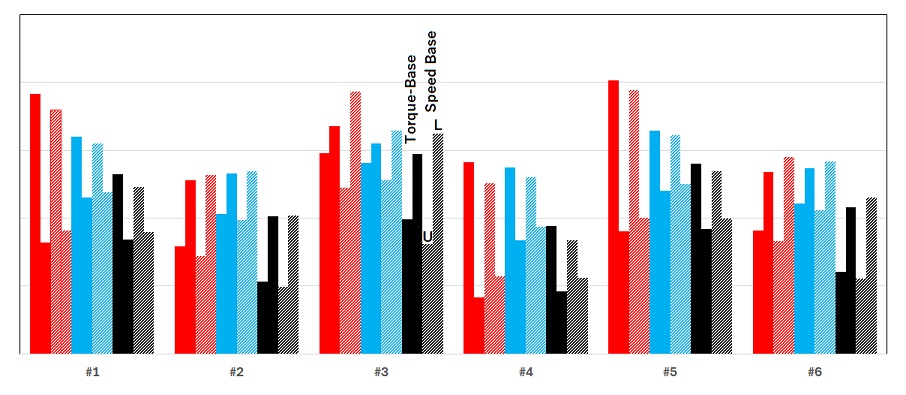

b) Forward Flight

Figure b)

shows the operational conditions of #1 to #6 rotor set when the

vehicle of which center of gravity offset from the Z-axis

flying horizontally forward., using speed-based control or torque-based

control.

In this

case, there are differences in the thrust of each rotor set in

order to control the pitching and rolling attitudes. Then the yawing

torque

is generated due to unbalancing of *drag force acting on each rotor and

gravity acting on the forward-leaning vehicle, and the upper and lower

rotors are differentially operated to maintain the yawing angle.

It can be seen that there are differences in operating

conditions between speed-based control and torque-based control.

*Drag force:

Resistance force which is parallel to the rotor rotational plane and acts in

the opposite direction to the flight direction

a) Hovering

b) Forward Flight

(3) Comparison

of Power Consumption between Contra-Rotating Rotor and Single Rotor

The table below shows a

comparison of the power consumption of a Quad-copter

with contra-rotating rotor and a Octo-copter

with single-rotor, both of which have rotors with the same

specifications.

In

order to

eliminate the effects of losses in the motor and ESC, the total power consumed

by the eight rotor is shown instead of

electric

power consumption in the comparison.

In the

table, it can be noticed that the single rotor consumes about 13-14% less power

in both hovering and forward flight.

Like this

example, if the total rotor rotating area is the same, the rotor efficiency

(N/kW) will generally be higher for a single rotor.

So,

when using contra-rotating rotors, it can be said that consideration on rotor

efficiency by simulations should be made advance.

<Comparison of Power between Contra Rotating and Single>

|

Vehicle

Type |

Num.

of Rotor |

Rotor

Dia. |

Differential

Control Method |

Hovering |

Forward

Flight(10m/s) |

|

Quad-copter |

(Dual)

x (4) =8 |

0.51m |

Speed Base |

5.853kW |

5.423kW |

|

Torque Base |

5.86kW |

5.454kW |

|||

|

Octo-copter |

(Single) x(8)=8 |

0.51m |

− |

5.084kW |

4.655kW |

Wha’s

New @V3.3

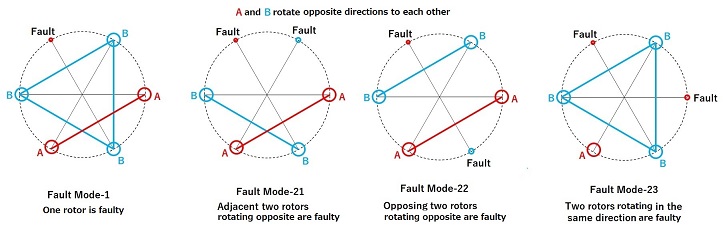

The fault tolerance of the vehicle can be evaluated.

Please

watch!

↑

↑ ↑ ↑

Click pictures above to watch the movie

・It is possible to predict whether the vehicle

can fly stably at the target speed (X, Y, Z direction) maintaining the

appropriate yaw, pitch,

and roll

angles by reconstructing the thrust distribution of each rotor, when either

rotor is damaged and lost the thrust.

・Up to 2 damaged rotors can be selected by GUI.

◆Features Fault Tolerance Prediction Method of DroneV

・In general, Dynamic Modeling and differential equation solvers such

as Matlab/Simulink are used for motion analysis of

drones.

On the other hand, DroneV uses Kinematic Modeling and inverse analysis with a

non-linear simultaneous equation solver

to find the solution of

the rotor thrust distribution for the vehicle to maintain the dynamic balance

at each time step.

・Expressing the difference between the two methods in simple manner,

Dynamic Modeling reproduces the process of controlling

the thrust distribution of each rotor sensing the response of

flight speed and attitude, while DroneV determines

directly

the thrust distribution to enable the vehicle to maintain a stable

attitude in target speed, and if no solution is found, it is determined

that the stable flight is impossible.

・Therefore, DroneV is suitable for

applications that require many case studies, such as fault tolerance

prediction, because it does not

require creating a control program ,

moreover the computational load is small.

Wha’s

New @V3.2

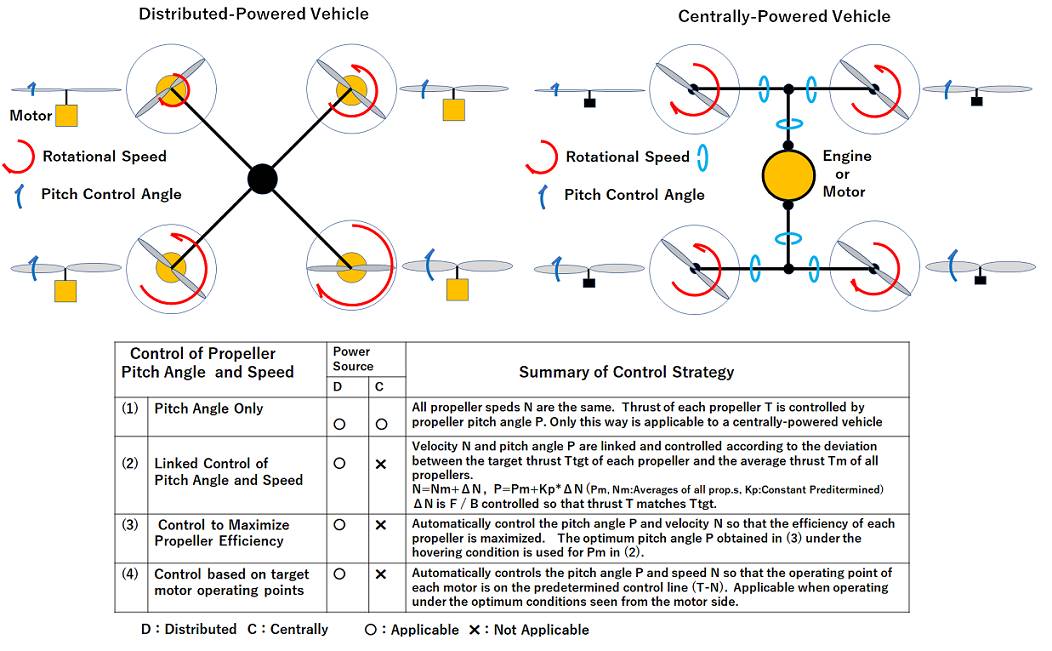

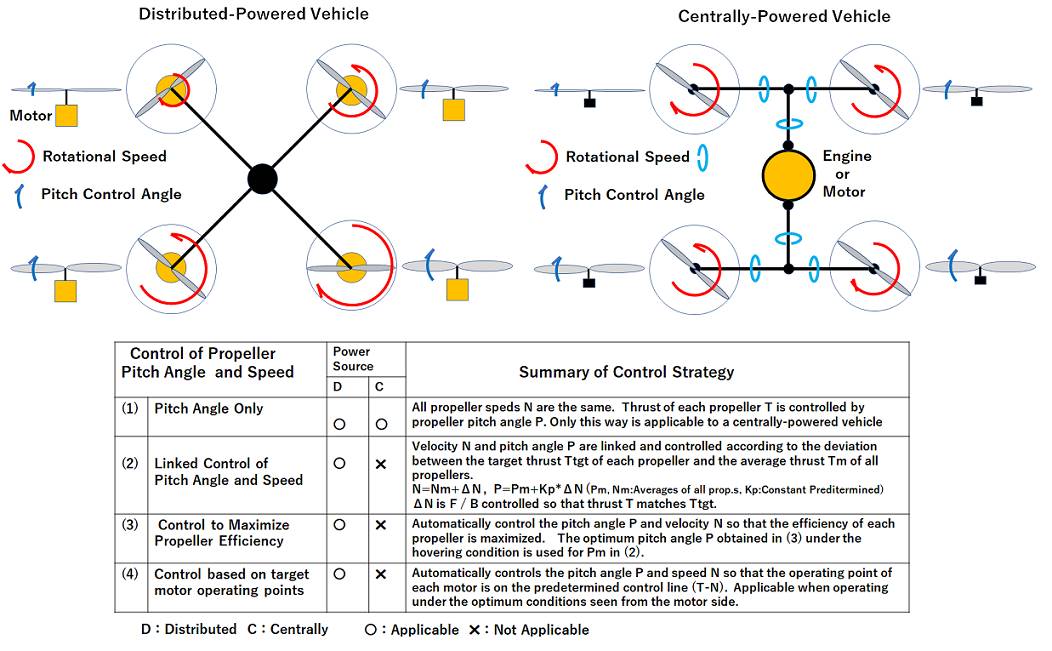

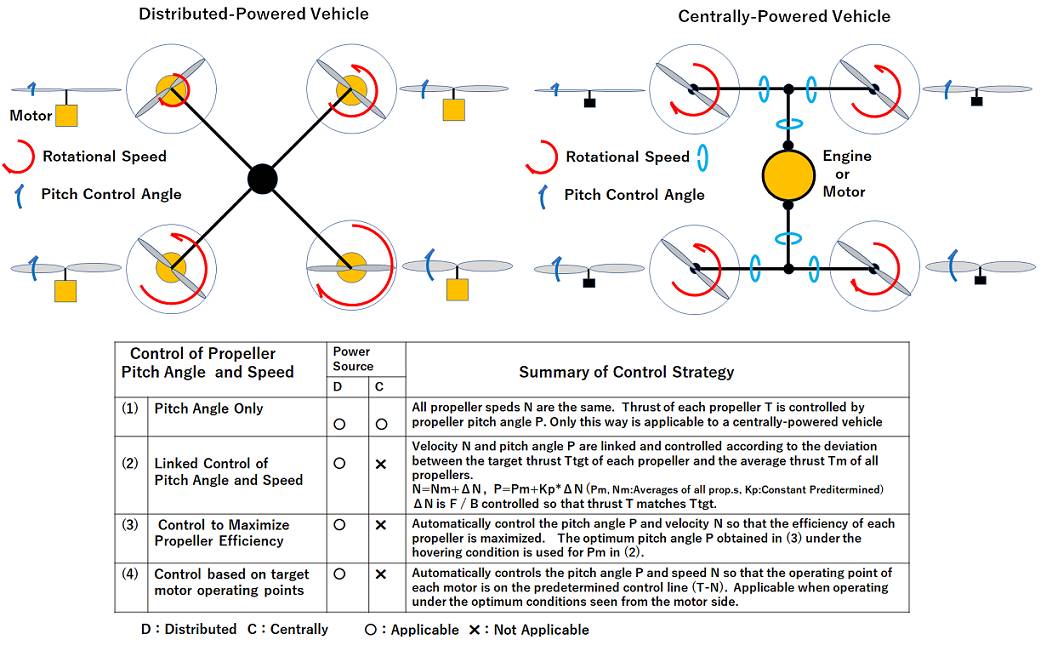

◆ Support

vehicle models equipped with variable pitch propeller (VPP)

Fixed pitch propeller (FPP: Fixed Pitch

Propeller) and variable pitch propeller (VPP: Variable Pitch Propeller) can be

selected.

Currently,

many drones use FPP, but in the future, especially large drones and sky cars

will be expected to have VPP’s for higher propeller efficiency

over a

wide flight speed range than conventional FPP.

V3.2

provides the simulation of the flight of an aircraft equipped with VPP in

addition to the conventional FPP.

◆Support

centrally-powered models installed a power source in the center of the aircraft

Since

VPP-equipped models are available, a ‘centrally-powered’ model mounting a power

source(engine or a motor) in the center, and drives

propellers

via

power transmission system Is added to vehicle configuration options.

What’s

New @V3.1

(1)

Motor drive system option

Sine

wave drive , voltage phase vector control, and field

weakening control in high speed area was assumed.

↓

Support

a square wave drive, fixed voltage advance control, and without field weakening

control in high speed area.

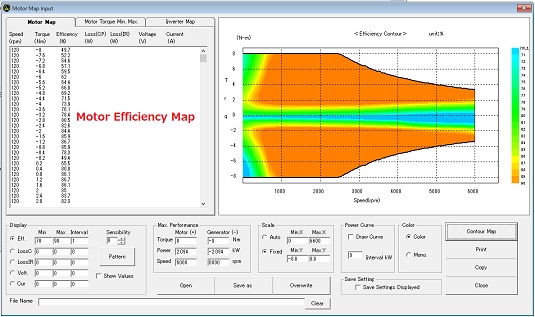

(2)

Support motor efficiency map input

Both motor and inverter efficiency maps can be

created by MS-Excel in a vehicle model.

<Basic Features of the Product>

◆Possible to fly a three-dimensional flight

course while changing the attitude (yaw, pitch, and roll).

-The

flight of vehicle even with complicated flight patterns can be simulated

without detailed programming

such as a motor control, because of applying

an inverse analysis method

◆An impact of the crosswinds defined with a

three-dimensional vector can be predicted.

◆3D coordinates of the center of gravity and

aerodynamic center can be defined, and the allowable center of

gravity position range for safety flight can

be predicted.

◆Flight course can be defined by either time to

X, Y, Z direction velocity component or time to X, Y, Z spatial position.

-In the

case of the course by position input, the specified points can be connected

with spline curves, corner R and straight lines, or straight

lines.

Moreover,

the flight speed is automatically determined for each route to pass the

specified position point at the specified time.

Technical

Report

◆Technical

Report: High Power & Low

Emission Engine for Next Generation Hybrid Drone